|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| EZ Maintenance for Windows |

|

| EZ Maintenance™ is also

available as a Windows's

program for the user seeking

a flat priced maintenance

software solution.

|

| |

|

| Partial Client List |

|

| EZ Maintenance™ for Windows

|

| EZ Maintenance™ WEB |

| |

|

|

|

| Features |

|

- Schedule All Maintenance

- Equipment & Vehicles

- Full Inventory Control

- P.O.s, RFBs, Invoices

- Work Orders, Bar Coding

- Emergency Work Orders

- Email Alerts

- QuickBooks Link

- Send Work To Vendors

- Customer/Vendor Tracking

- Track Customers

- Maintenance Histories

- Access Passwords

- Supervisory Control

- And Much More!

|

|

| Contact Information |

|

Pinacia Inc.

5699 Kanan Road, #349

Agoura Hills, CA USA 91301

Phone: (818) 396-8550

Sales Support: ext. 1

Tech Support: ext. 2

Fax: (818) 396-3524

info@pinacia.com

|

|

|

|

|

|

|

Previous

Section:

Viewing Maintenance

Due Viewing Maintenance

Due |

Next

Section:

Maintenance Due Report |

Click Here to see a demonstration video on Work Orders for Equipment Maintenance, which includes a demonstration on how to create work orders in EZM Web.

Creating Work Orders (For Scheduled Preventive Maintenance)

In EZM Web, to create a scheduled preventive maintenance work order for a

piece of equipment, you just select that maintenance event from the list of

scheduled maintenance events for that piece of equipment and click to create

a work order for it!

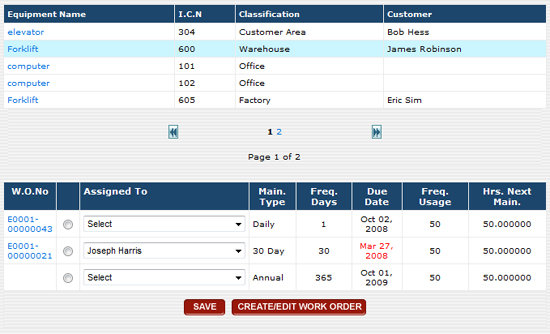

On this page, you can view all of the scheduled maintenance events for a

particular piece of equipment. Notice that, in the screenshot below, all of

the equipment currently tracked by EZM Web is listed above, and below that

the list of all scheduled maintenance events for the selected piece of

equipment is shown:

Notice that the due date of one of the scheduled maintenance events is shown

in red text; this means that the preventive maintenance event is overdue.

However, a work order has been created for it; as the number for that work

order is shown in the W.O. No. (Work Order Number) column

on the far left. If no work order has been created for a scheduled

maintenance event, no work order number is shown, as is the case with the

"Annual" maintenance shown here. Here you can also see who each work order

is assigned to; the second work order is assigned to "Joseph Harris".

To view the details for a work order, just click on its work order number!

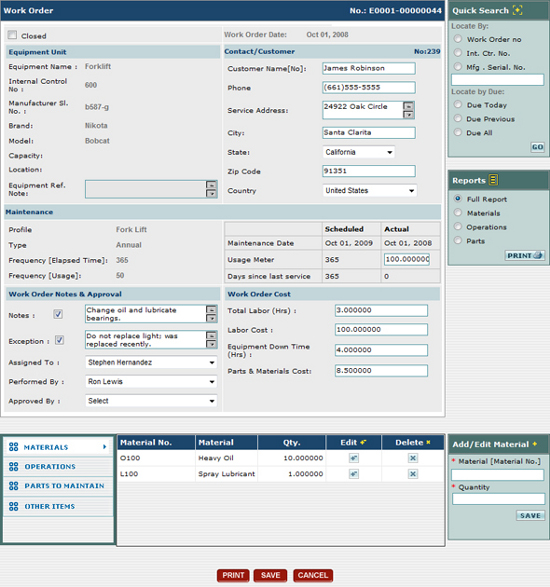

Now, to create the new work order, just select one of the scheduled

maintenance events and then click on the CREATE/EDIT WORK

ORDER button, which opens up the following page where you fill

in the details for the new work order:

On this page, the following information is displayed:

- Information about the piece of equipment for which

you are creating the work order.

- Information about the customer who owns this piece

of equipment, if the equipment doesn't belong to your company and

you are servicing it for someone else.

- The type of maintenance being performed.

- Notes about the work order and who the work

is assigned to, who is performing the

work, and who has approved it.

- The total costs for the work and equipment

down time.

- The materials, replacement parts and operations/steps

necessary to complete the maintenance.

When you create a work order, the materials, replacement parts, and

operations/steps necessary to complete the work are all filled in

automatically. However, if you need to make changes to the materials, parts,

and operations on the work order to accommodate a particular instance, you

can do that as well!

Once the work has actually been completed, all you have to do is mark the

work order as closed and it goes into the equipment maintenance history

along with all other closed work orders:

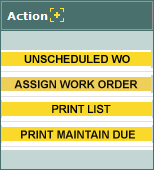

Creating Unscheduled Work Orders

EZM Web maintenance software also allows you to create unscheduled work

orders that aren't part of the normal maintenance schedule for unexpected

equipment breakdowns. This is done by using the UNSCHEDULED

WO button:

After clicking on this button, a page similar to the one at which you create

a scheduled work order will load. Just select the piece of equipment for

which you want to create the work order and the type of maintenance you want

to perform!

|

Previous

Section:

Viewing Maintenance

Due Viewing Maintenance

Due |

Next

Section:

Maintenance Due Report |

|

|

|

|

|