|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| EZ Maintenance for Windows |

|

| EZ Maintenance™ is also

available as a Windows's

program for the user seeking

a flat priced maintenance

software solution.

|

| |

|

| Partial Client List |

|

| EZ Maintenance™ for Windows

|

| EZ Maintenance™ WEB |

| |

|

|

|

| Features |

|

- Schedule All Maintenance

- Equipment & Vehicles

- Full Inventory Control

- P.O.s, RFBs, Invoices

- Work Orders, Bar Coding

- Emergency Work Orders

- Email Alerts

- QuickBooks Link

- Send Work To Vendors

- Customer/Vendor Tracking

- Track Customers

- Maintenance Histories

- Access Passwords

- Supervisory Control

- And Much More!

|

|

| Contact Information |

|

Pinacia Inc.

5699 Kanan Road, #349

Agoura Hills, CA USA 91301

Phone: (818) 396-8550

Sales Support: ext. 1

Tech Support: ext. 2

Fax: (818) 396-3524

info@pinacia.com

|

|

|

|

|

|

|

Previous

Section:

Setting

Up EZ Maintenance Setting

Up EZ Maintenance |

Next

Section:

Creating

Work Orders |

|

/video/

|

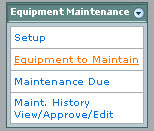

| Viewing

and Entering Equipment |

Viewing List of Entered Equipment

To get a listing of all the equipment that has been entered into the system,

you simply click the "Equipment To Maintain" link from the Equipment

Maintenance menu in the left side navigation bar.

The equipment appears in a listing similar to the one shown here:

This screen displays information on each piece of equipment that has been

entered into EZM Web.

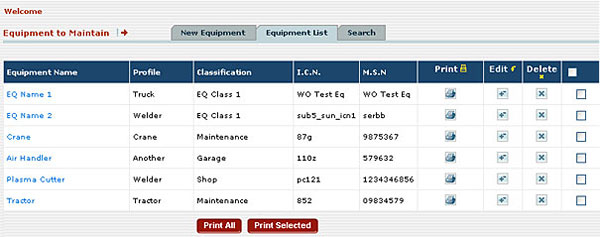

Equipment Class Filter The "Equipment

Class Filter" under the Quick Search box to the right is where you can

filter your equipment listing to show only certain pieces of equipment based

on their classification if you choose to. Simply choose the specific Class

Filter from the drop-down menu, click "go", and only the equipment that has

that classification will be displayed. Equipment Class Filter The "Equipment

Class Filter" under the Quick Search box to the right is where you can

filter your equipment listing to show only certain pieces of equipment based

on their classification if you choose to. Simply choose the specific Class

Filter from the drop-down menu, click "go", and only the equipment that has

that classification will be displayed.

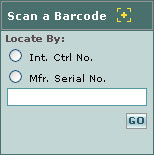

Locate By You can quickly locate a

piece of equipment if you already know a certain detail about it by using

the "locate by" function which is also located in the quick search box. Just

select the criteria you want to search by, type in the information and press

"go".

Scan a Barcode to Locate Select the

Barcode scan format, (Either Internal Control number or Manufacturer Serial

number) then scan the equipment Barcode, and click Locate. This will bring

you to the equipment whose barcode you've scanned. Scan a Barcode to Locate Select the

Barcode scan format, (Either Internal Control number or Manufacturer Serial

number) then scan the equipment Barcode, and click Locate. This will bring

you to the equipment whose barcode you've scanned.

|

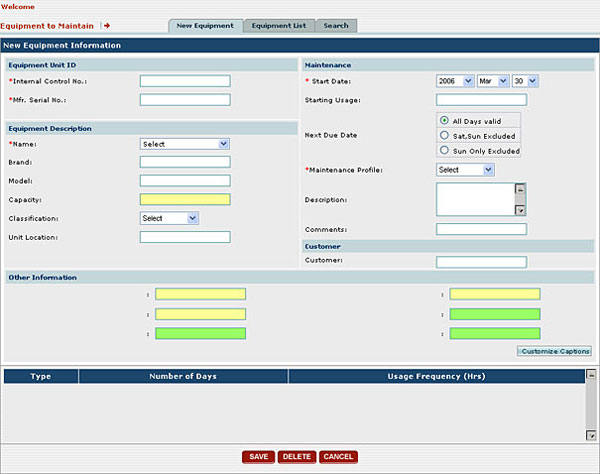

Entering New Equipment To create a

new Equipment Record in EZM Web, you simply click the "New Equipment" tab

and you'll see this screen.

The following fields are required and should have information in

them.

Internal Control Number: This is an

identification number assigned to a particular piece of equipment.

Manufacturer's Serial Number: This is

also a required field but if this information is not available, simply make

it the Internal Control Number.

Name: Here you select one of the

equipment names that were created in the equipment Setup Menu from the drop

down menu.

Start Date: All maintenance is

scheduled from this date forward based on the frequencies that were provided

in the equipment's profile.

Maintenance Profile: (previously

created in the SETUP menu) When adding a piece of equipment, by simply

selecting the corresponding Maintenance profile, EZM Web will automatically

schedule all the various preventive maintenance events that need to be done

for that particular kind of equipment, thus saving a great deal of time and

trouble in setting up equipment.

THE OTHER FIELDS IN THIS SCREEN ARE OPTIONAL

Customize Captions: This option allows

you to input your own fields to describe your equipment even further. For

example, if you wanted to enter in a Warranty Date field where your

operators would have to fill out the date, you would create the field with

this feature.

Click here to view

sample reports. |

Previous

Section:

Setting

Up EZ Maintenance Setting

Up EZ Maintenance |

Next

Section:

Creating

Work Orders |

|

|

|

|

|